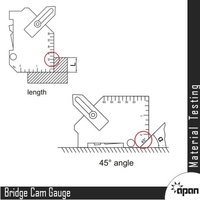

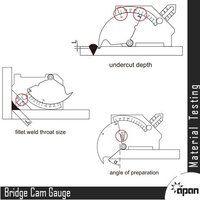

Bridge Cam Gauge

Product Details:

Product Description

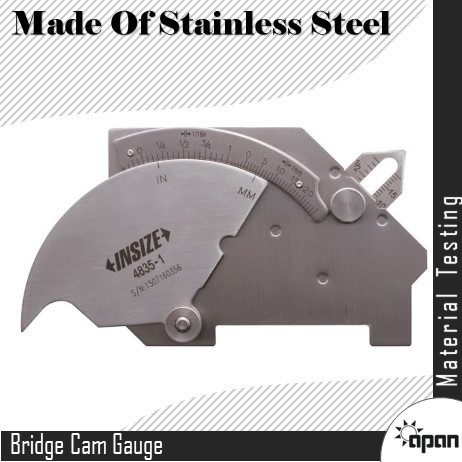

The material of the gauge is high strength stainless steel, then the ruler is not easy to bend and wear, never rust and it also ensure accurate measurement. Weld inspection ruler with fastening screws can be fixed at any point, then it is convenient for reading when you do the measurement the ruler surface is mechanical grinding, no glitches.

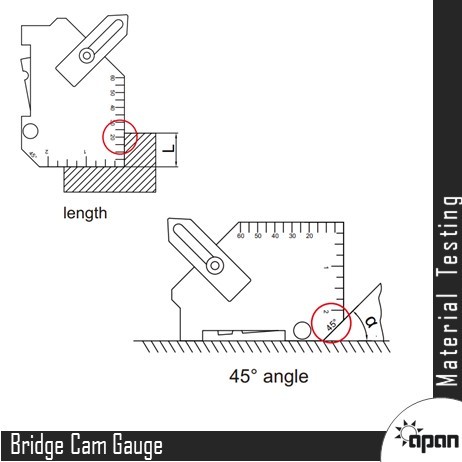

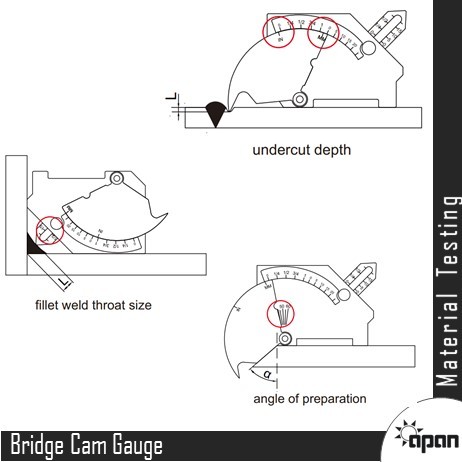

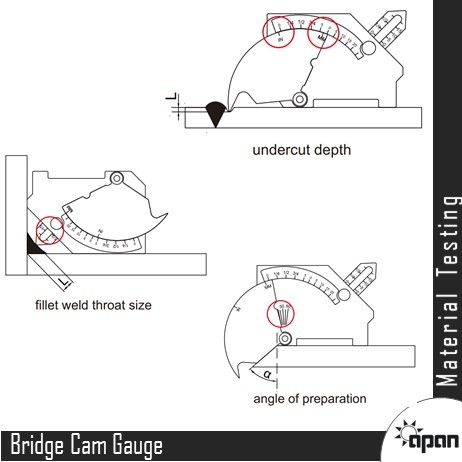

An essential tool for rapidly checking the dimensions of weld preparations, butt welds and fillet welds -

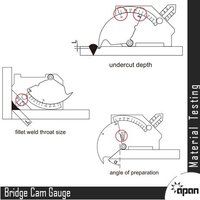

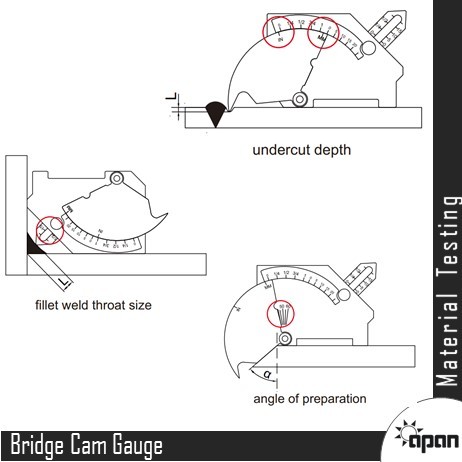

- angle of preparation

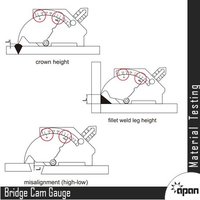

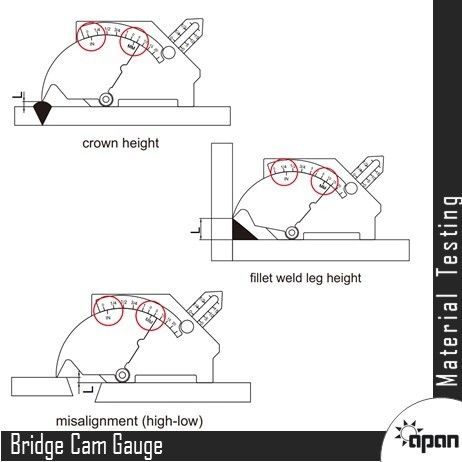

- misalignment

- fillet weld leg length/excess weld metal

- fillet weld throat

- undercut

Used across the world by welding engineers, inspectors, NDT operators, quality control staff and welders.

Made of stainless steel

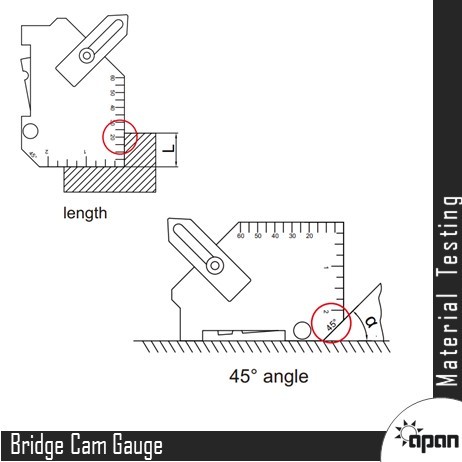

- Used for measurement: Crown height, fillet weld leg height, misalignment (high-low), undercut depth, fillet weld throat size, angle of preparation, length.

- This tough, easy-to-use gauge is made from stainless steel throughout and finished to a high standard. Its parallax-free scales are conveniently graduated in metric and imperial units.

- Ideal for general fabrication work in the shop or on-site, it helps you achieve the correct weld profile, reduce the risk of product failures, increase productivity and prevent materials wastage.

FAQs

What is the use of bridge cam gauge?

The Bridge Cam Gauge, also referred to as the Cambridge gauge, is a reliable, precise gauge that may be used in the shop or on the job site. It can gauge the thickness of the throat and legs of the fillet welds, the height of the weld reinforcement, the depth of the undercut, the misalignment, and the preparation angle.wear, increased expenditures for upkeep, and, at its

Does thickness increase with gauge?

A sheet metal measure (at times spelled gage) demonstrates the standard thickness of sheet metal for a particular material. As the check number builds, the material thickness diminishes.

Do weld gauges need to be calibrated?

The actual welding force at the weld is precisely measured by a weld force gauge. These instruments must be calibrated since using a weld force that is either too low or too high might result in issues including cracking, indentation, ejection, and weak welds.wear, increased expenditures for upkeep, and, at its

Other Products in 'Industrial Metrology Tools' category

|

APAN ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry