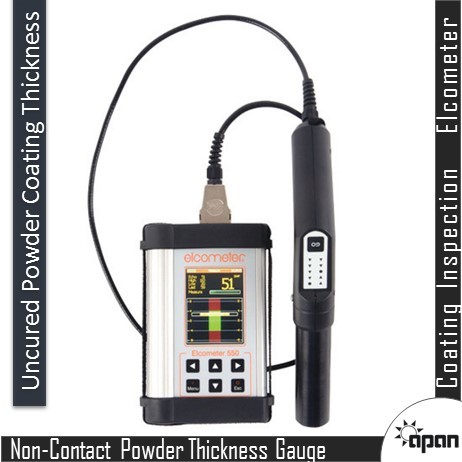

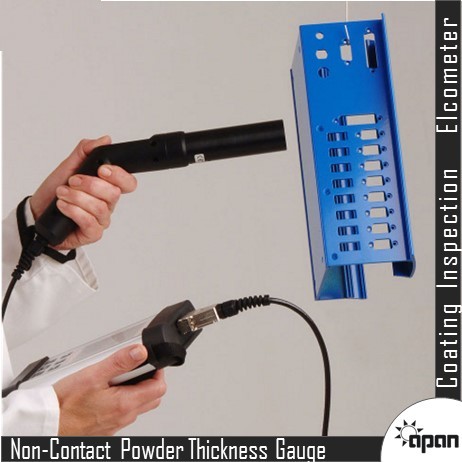

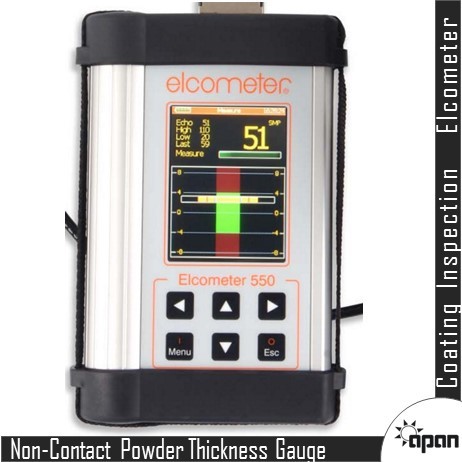

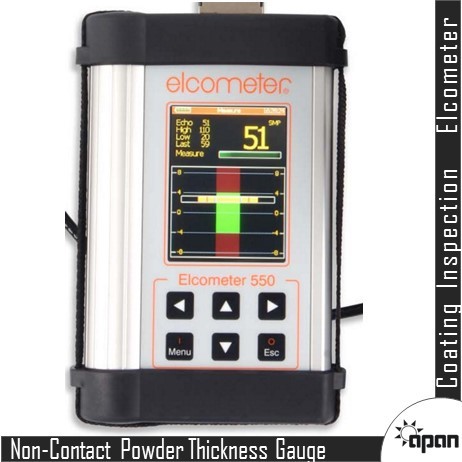

Non-Contact Powder Thickness Gauge

Product Details:

Product Description

As an Authorized dealer we are engaged in providing the broad assortment of "Coating Inspection Instrument" for wide range of applications. By carefully controlling the thickness of powder applied to a product, you ca minimise your powder usage are ensure the quality of your coating.

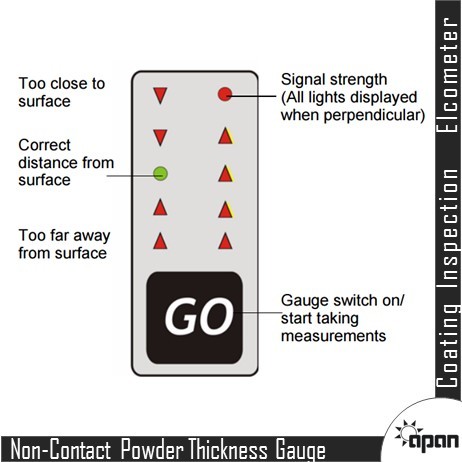

As contact measurement solutions damage the finish and do not predict the cured coating thickness, measuring the powder thickness pre-cure requires a non-contact solution.

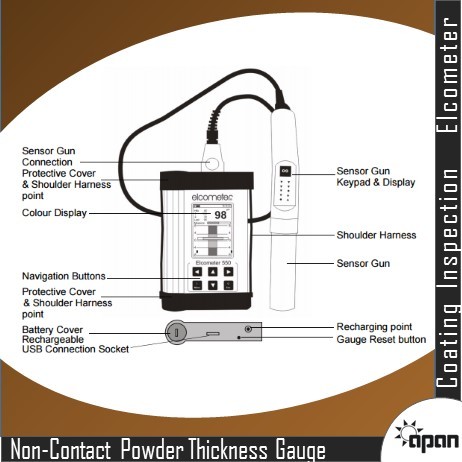

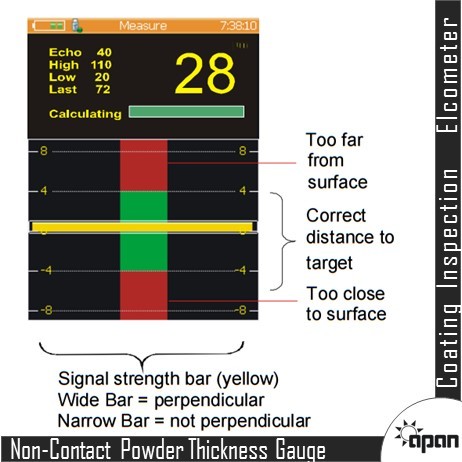

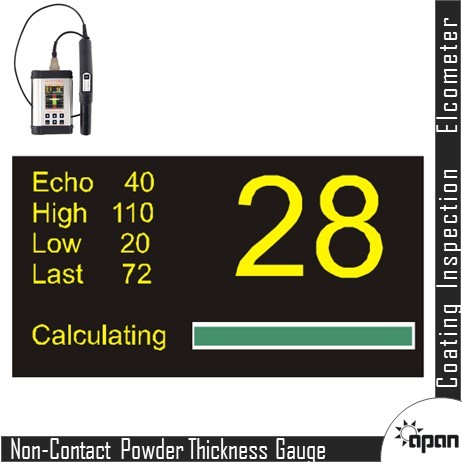

Using third generation proven airborne ultrasonic technology, the new Elcometer 550 accurately predicts cured coating thickness by non-contact measurement of coating powders.

Easy to use

Reliable

Enhanced Technology

Specification

Display | 3 1/2 Inches (90mm) QVGA Colour LCD |

Power Supply | Rechargeable NIMh battery, up to 7 hours continuous use |

Measurement Range | 30 - 110um (1.18 - 4.4mils) |

Resolution | 1 um (0.04mils) |

Measurement Accuracy | +-5um (+-0.25mils) or +-5% of the coating thickness, whichever is greater |

Measurement Offset Distance | 18mm (0.71") from the coated substrate |

Measurement Area | 1m2 (0.04sq in) |

Operating Temperature Range | 10‚°C to 35‚°C (50:F to 95‚°F) |

Units | um / mils switchable |

Dimensions | 115 x 185 x 35 mm (4.6 x 7.4 x 1.4") |

Weight | 900g (1.9lbs) |

Elcometer 550 Gauge with rechargeable battery, universal charger unit and cable, sensor gun and lead, shoulder hamess, reference block, USB-PC transfer cable, carry case, test certificate and operating instructions

Other Products in 'Coating Inspection' category

|

APAN ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry