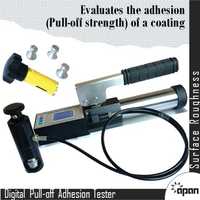

Digital Pulloff Adhesion Tester

Product Details:

Product Description

Various Types of Adhesion tester (Analog and Digital both types ) are available.

- Pull-Off Adhesion Testing

- Push Off Adhesion Testing

- Cross Hatch Adhesion Tester.

Pull-off Test

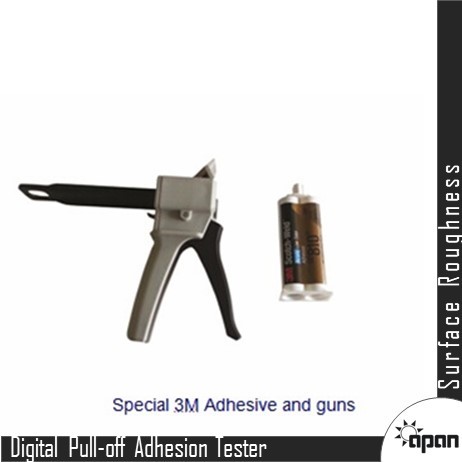

Adhesion of a single coating or a multi-coat system of paint, varnish or related products is assessed by measuring the minimum tensile stress necessary to detach or rupture the coating in a direction perpendicular to the substrate. This method maximizes tensile stress as compared to the shear stress put by other methods such as scratch adhesion and results may not be comparable. The test is performed by securing a loading fixture (dolly) perpendicular to the surface of the coating with an adhesive. After the adhesive is cured, a testing apparatus is attached to the loading fixture and aligned to put tension perpendicular to the test surface. The force put is gradually increased and monitored until either a plug of coating material is detached, or a specified value is reached.

Digital pull-off adhesion tester is a portable, hand-operated instrument which is used to measure the force required to pull a specified test diameter of coating away from its substrate using hydraulic pressure.

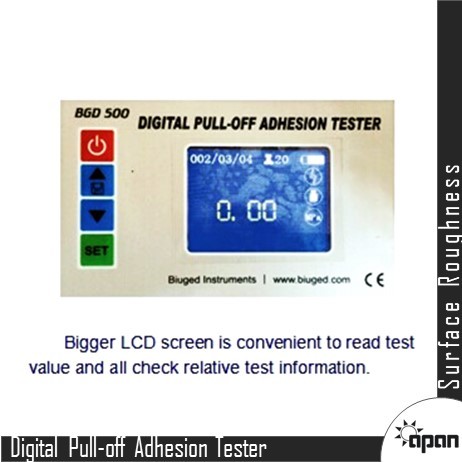

The pressure is displayed on a digital LCD and represents the coatings strength of adhesion to the substrate.

It evaluates the adhesion (pull-offstrength) of a coating by determining the greatest tensile pull-off force that it can bear before detaching. Breaking points, demonstrated by fractured surfaces,occur along the weakest plane within the system consisting of dolly, adhesive,coating layers and substrate.

Advantage:

- Portable design, can be used anywhere.

- Built-in rechargeable lithium battery, no need any external power source.

- Selectable directly four different sizes dolly for different resolution and testing range

- Get the testing results from LCD directly.

PRECISE

- Each PsiaTesters pressure system is calibrated towithin 1% accuracy by NIST traceable load cells

- High-precise professional sensor ensures 0.01MPa resolution

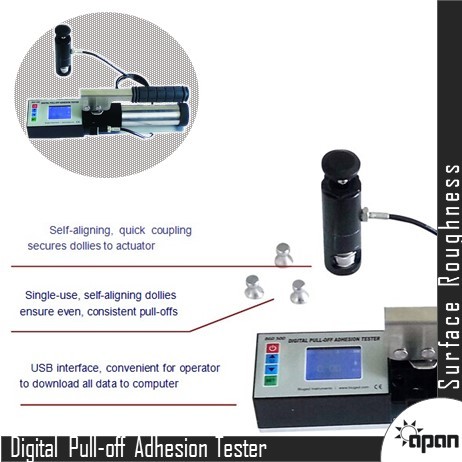

- Self-aligning dollies ensure to get a reliable testing results for smooth or uneven surfaces.

- Supply with calibration certificate

INTELLIGENT

- Store all test results includes Max.pull-off power,pull-off rate, dolly size and timeautomatically

- Two units MPa and psifor selection and can be converted automatically.

- No need any software, when connecting the computer, operator can read all data directly which is recorded during testing.

- Showing pull-off rate allows users monitor and adjust pull speed according to different test requirements.

DURABLE

- Waterproof, dustproof and shockproof design meets any harshest operating environment

- Strong plastic carrying case

Specifications

- Dolly Size: 20mmStandard10mm14mm50mmOptional

- Resolution: 0.01MPa1psi

- Accuracy: 1% Full scale

- Max. Pull-off Pressure

- 10mm dolly 0-80 MPa

- 14mm dolly0-40 MPa

- 20mm dolly0-20 MPa

- 50mm dolly0-3.5 MPa

- PowerBuilt-in rechargeable lithium battery, and standard configuration charging adapter.

- Adhesion Tester Size360mm75mm115mmL x W x H

- Adhesion Tester Weight3KG

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

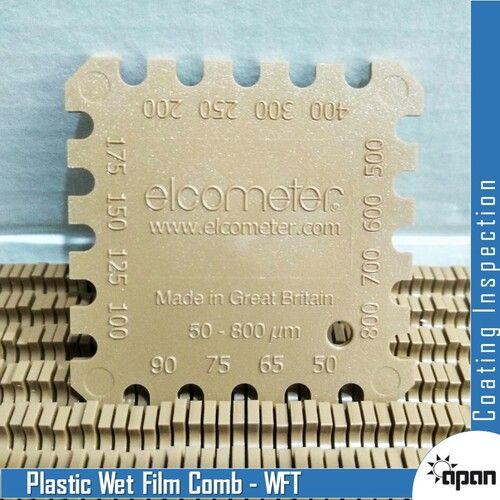

Other Products in 'Coating Inspection' category

|

APAN ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry