Impact Tester

Impact Tester Specification

- Frequency

- 50 Hz

- Accuracy

- 0.1 J

- Port Size

- Standard

- Specimen Size

- 10 x 10 x 55 mm

- Number of Specimens

- 1 per test

- Interface Type

- Panel Mounted

- Features

- Robust Construction, High Accuracy, Easy Operation

- Response Time

- Instantaneous

- Measuring Range

- 0-300 J

- Max Height

- 550 mm

- Power Supply

- 220 V AC, 50 Hz

- Equipment Type

- Impact Tester

- Application

- Material Impact Strength Testing

- Temperature

- 10C to 40C

- Automation Grade

- Manual

- Resolution

- 0.01 J

- Test Range

- Up to 300 J

- Operating Voltage

- 220 V

- Humidity

- Up to 85% RH

- Mounting Type

- Bench Top

- Display Type

- Analog / Digital

- Usage

- Industrial

- Capacity

- Specimen-dependent

- Machine Weight

- 95 kg

- Test Speed

- 2.9 m/s

- Test Width

- 10 mm

- Test Stroke

- 350 mm

- Control Mode

- Manual

- Color

- Blue/Grey

- Material of Construction

- Mild Steel with Powder Coating

- Safety Features

- Protective Shield, Emergency Stop

- Dimension (L x W x H)

- 800 x 400 x 850 mm

- Pendulum Weight

- Standard as per selected energy level

- Standards Compliance

- IS 3766, ASTM E23, DIN EN ISO 148-1

- Pendulum Type

- Izod / Charpy (as per configuration)

- Calibration

- Certified as per IS/ASTM/DIN standards

Impact Tester Trade Information

- Certifications

- ASTM D 2794, JISK 5400, CNS 10756

About Impact Tester

The Impact Tester has been designed to test the impact endurance of coated material, when impacted by a falling weight at specified points. The purpose of the test is to see if test specimens can resist the effect of rapid impact testing.

The principle of the test is that a coated test specimen is impacted by a falling weight, at a fixed height; thus checking the damage or deformation of the test specimen.

Impacting test for painting and coating materials is to use an impacting head with various round angles to touch the specimen in the beginning, and then a selected weight free dropping from a certain height to hit the impacting head to impact the specimen. Running the same way to test three more specimens, and put and leave them for an hour, and then watch if there is crack on the painting.

The Impact Tester can also be used on paintings with coated materials. The same procedure is followed, using various impact heads or needles to drop freely onto the test specimen from a certain height. This is performed three times on the same test specimen, which is then left to stand for one hour. The test specimen is then checked for any cracking on the painting.

It is compatible with ASTM D 2794,JISK 5400,CNS 10756.

Main Technical Parameters

- Impact height / Instrument scale Length50-500mmgrade 0mm

- Impact weight / Mass of hammer300g500g1000g

- Impact head fixed base / Piercer specification: 1/2", 1/4", 1/8", 1/16", 3/16in

- Notch diameter on the bolster block1/21/41/81/163/16in

The Impact Tester can also be used on paintings with coated materials. The same procedure is followed, using various impact heads or needles to drop freely onto the test specimen from a certain height. This is performed three times on the same test specimen, which is then left to stand for one hour. The test specimen is then checked for any cracking on the painting.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Material Testing Category

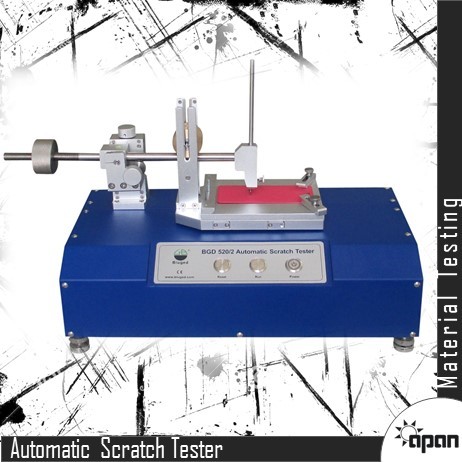

Automatic Scratch Tester

Response Time : <1 sec

Measuring Range : 1N 50N (Scratch Load)

Control Mode : Automatic & Manual

Application : Scratch Resistance Testing for Coatings, Paints, Platings, Sheets

Accuracy : 1%

Specimen Size : 100 50 mm (max)

Linear Abrasion Tester

Response Time : Realtime monitoring

Measuring Range : 0999,999 cycles

Control Mode : Digital programmable control

Application : Assessment of abrasion resistance for coated, painted, and printed surfaces

Accuracy : 1 cycle

Specimen Size : Maximum 100 mm 100 mm

Ultrasonic Hardness Tester

Response Time : 1 second

Measuring Range : HV 201740, HRC 20.468.0, HB 20527, HS 32.599.5, HL 170960

Control Mode : Digital Control

Application : Metals Hardness Measurement

Accuracy : 3 HL

Specimen Size : Minimum thickness 3mm

Leeb Hardness Tester

Response Time : Immediate (realtime display)

Measuring Range : 170960 HL (Leeb) / Converts to HRC, HB, HV, HS, and others

Control Mode : Manual

Application : Testing the hardness of steel, cast steel, alloy tool steel, stainless steel, gray cast iron, nodular cast iron, cast aluminium, brass, bronze, copper, and other materials

Accuracy : 6 HL (0.5% at 800 HL)

Specimen Size : Minimum mass: 2 kg (with coupling), Minimum thickness: 3 mm

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry